What is the composition of Graphite end mills products

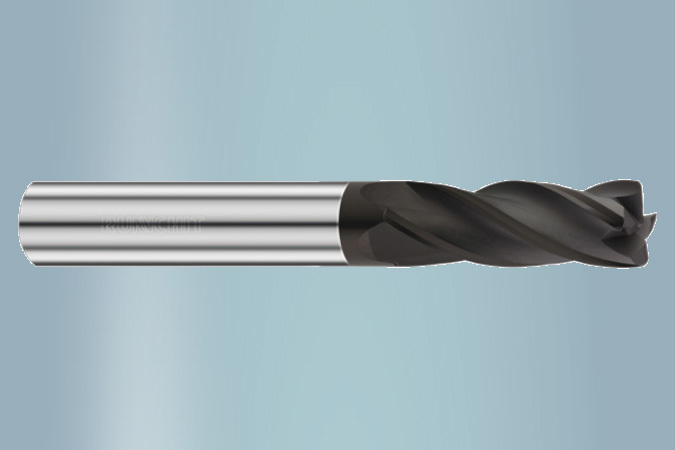

Graphite end mills are diamond-coated milling cutters used to process graphite and alloy non-ferrous materials in modern industry.

The composition of Graphite end mills:

1. Coarse-grained tungsten steel substrate (1-6UM), because the diamond coating has a coarser grain;

2. Cover 8-12UM unilateral thickness diamond coating.

3. The Graphite end mills manufacturer tells you the sharper geometry angle of the cutter body compared with ordinary milling cutters.

Because of its use of diamond coating, its heat insulation performance is remarkable, and with the superior high wear resistance of diamond, the performance of diamond coated Graphite end mills in the processing process is better than that of ordinary tungsten steel milling. The knife is increased by 10-15 times. The Graphite end mills manufacturer tells you that this saves tool change time and avoids the trouble of tool marks caused by multiple tool changes. Great cost savings.

Graphite end mills have the right geometric angle to help reduce the vibration of the tool. Conversely, the graphite workpiece is not easy to chip.