Graphite end mills are commonly used knives for graphite processing

- Categories:Information

- Author:

- Origin:

- Time of issue:2021-11-01 10:23

- Views:

(Summary description)Graphite end mills manufacturers tell you that graphite is very expensive. For example, white steel knives can be processed. You may need to sharpen the knives every 15 minutes.

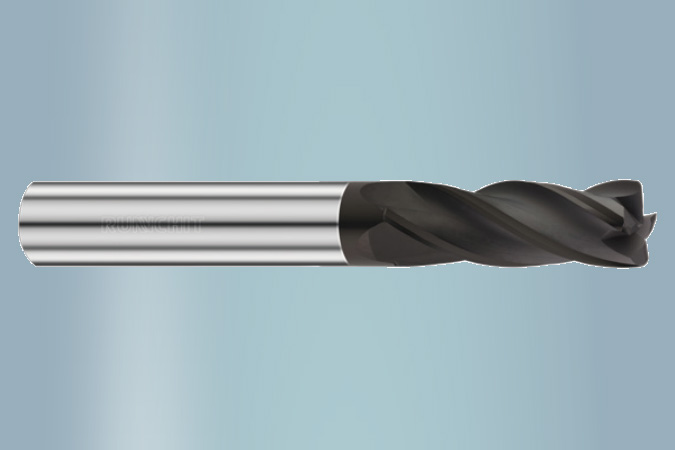

Graphite end mills are commonly used knives for graphite processing

(Summary description)Graphite end mills manufacturers tell you that graphite is very expensive. For example, white steel knives can be processed. You may need to sharpen the knives every 15 minutes.

- Categories:Information

- Author:

- Origin:

- Time of issue:2021-11-01 10:23

- Views:

Graphite end mills manufacturers tell you that graphite is very expensive. For example, white steel knives can be processed. You may need to sharpen the knives every 15 minutes. Then there are tungsten steel knives, which are much better for white steel knives. Generally, the knives used in graphite processing are commonly used, and the diamond knives are better. If you have silver, you can try diamond knives. They are super easy to use, but they are expensive.

Graphite end mills are diamond-coated milling cutters used to process graphite and alloy non-ferrous materials in modern industry.

Due to the use of diamond coating, its heat insulation performance is remarkable, coupled with the superior high wear resistance of diamond, the performance of diamond coated Graphite end mills in the processing process is better than that of ordinary tungsten steel milling cutters. Increase by 10-15 times. It saves time for tool change and avoids the trouble of tool marks caused by multiple tool changes. Great cost savings.

The Graphite end mills manufacturer tells you to first deposit the boron-doped diamond film on the drill bit, and then use the PVD method to plate a layer of intermetallic compound (such as TiAlN, etc.), which effectively improves the tool’s performance while ensuring the strength of diamond processing. Anti-oxidation performance extends the tool life and application areas.

The Graphite end mills manufacturer tells you that polishing technology used for the refinement of diamond surface grains can usually obtain a smooth surface, but it will limit its application to tool materials with complex geometric shapes.

The Graphite end mills manufacturer tells you that by controlling the secondary nucleation conditions in the process of depositing the diamond film, a microcrystalline diamond coated end mill with a smaller grain size can be obtained. The tool surface roughness is very small. The Graphite end mills manufacturer tells you Compared with ordinary diamond coating, it has higher processing accuracy and wear resistance and durability, and it is a powerful tool for processing silicon and aluminum materials.

Professional tungsten Steel tool manufacturer !

Add : Room 701, No.24,1661 Lane, Jialuo Highway,

Jiading District, Shanghai 201800,P.R.China

Tel : 0086-15000368509

Email : henry@runchit.com

Email : rebecca@runchit.com

Fax :0086-21-59559687