金属加工用石墨立铣刀制造商教你如何正确选择和使用立铣刀

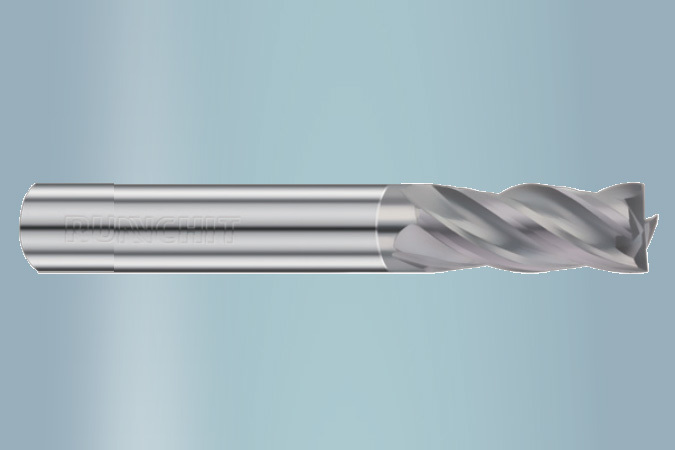

金属加工制造商的石墨立铣刀告诉您,立铣刀用于在铣床上开槽和加工精密轮廓零件。端铣刀的正确选择和使用对整个加工过程至关重要。立铣刀的材料和设计风格多种多样,应根据具体操作进行适当选择。此外,该工具具有多种外涂层,以延长工具寿命,降低操作温度,并起到冷却作用。

金属加工制造商的石墨立铣刀告诉您,立铣刀用于在铣床上开槽和加工精密轮廓零件。端铣刀的正确选择和使用对整个加工过程至关重要。立铣刀的材料和设计风格多种多样,应根据具体操作进行适当选择。此外,该工具具有多种外涂层,以延长工具寿命,降低操作温度,并起到冷却作用。

金属加工用石墨立铣刀制造商告诉您,切削速度的选择主要受待加工工件的材料影响,而进给速度的选择则直接由待加工工件和立铣刀的材料决定。如果你想知道具体的参数,可以看看国外一些工具制造商的工具样品。通常,他们会附上刀具切削参数选择表。金属加工制造商的石墨立铣刀告诉您,根据不同的行业和加工应用特性,难切割钛合金、高温合金、镍合金、不锈钢、铝、铜和高硬度材料的专用刀具具有很大的竞争优势。可根据客户的特殊要求定制各种工业非标工具。

Previous: HRC70硬质合金立铣刀主要两种切削方法

Next: 不锈钢球刀出现刀具振动怎么办

Professional tungsten Steel tool manufacturer

E-mail:rebecca@runchit.com

Tel:86-15000368509

Fax:021-59559687

Add:Building 1,No.97,Xinguan Road,Jiading District,Shanghai 201815,China

COPYRIGHT © 2025 RUNCHIT PRECISION TOOL(SHANGHAI)CO.,LTD

LEAVE A MESSAGE