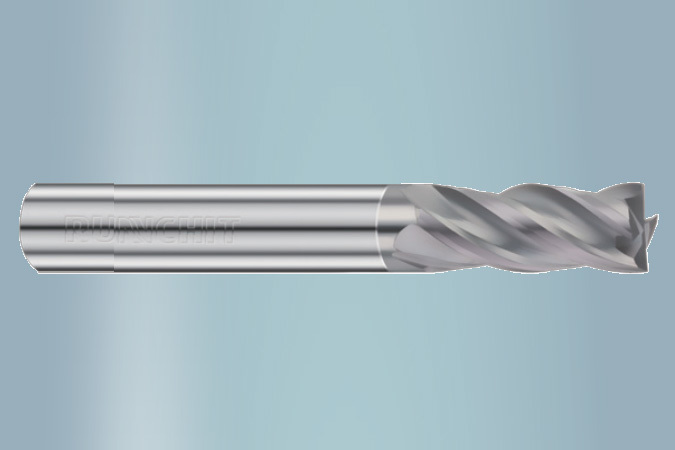

The HRC55 end mill cutting tools manufacturer will show you the purpose of end mills

The manufacturer of HRC55 end mill cutting tools tells you that the end mill is the most used milling cutter on CNC machine tools. The cylindrical surface and end surface of the end mill have cutters. They can be cut at the same time or separately. The manufacturer of HRC55 end mill cutting tools tells you that it is mainly used for face milling, groove milling, step face milling and profile milling.

Face milling

The manufacturer of HRC55 end mill cutting tools tells you that the end mill can be used for face milling. However, because its entering angle is 90°, the tool force is mainly radial force in addition to the main cutting force, which is easy to cause flexure and deformation of the tool bar, and also easy to cause vibration, which affects the processing efficiency. Therefore, HRC55 end mill cutting tools manufacturer I tell you that except for special reasons such as thin-bottomed workpieces that require small axial force or occasional reduction of tool inventory for face milling, it is not recommended to use end mills to machine flat surfaces without steps.

Side wall face milling

The HRC55 end mill cutting tools manufacturer tells you that most of the workpieces suitable for end milling have one or more sidewall surfaces perpendicular to the bottom surface (this surface is parallel to the milling machine spindle), which brings a feature that is not available in face milling Problem: The shape and accuracy of the side wall.